The system for attaching labels to cylindrical surfaces includes the following:

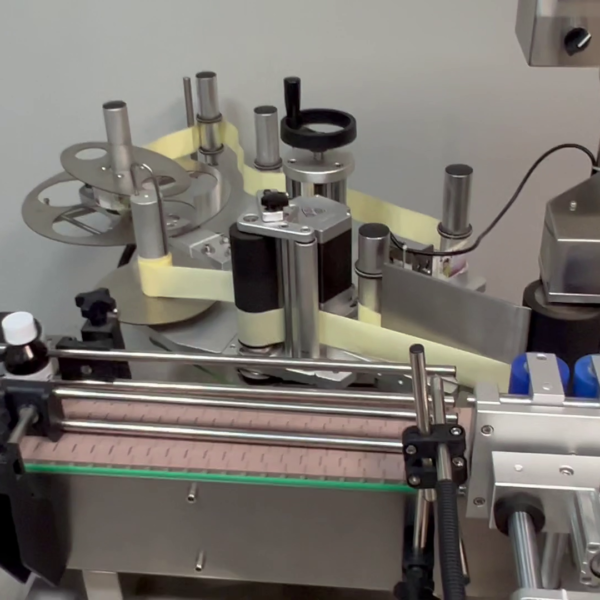

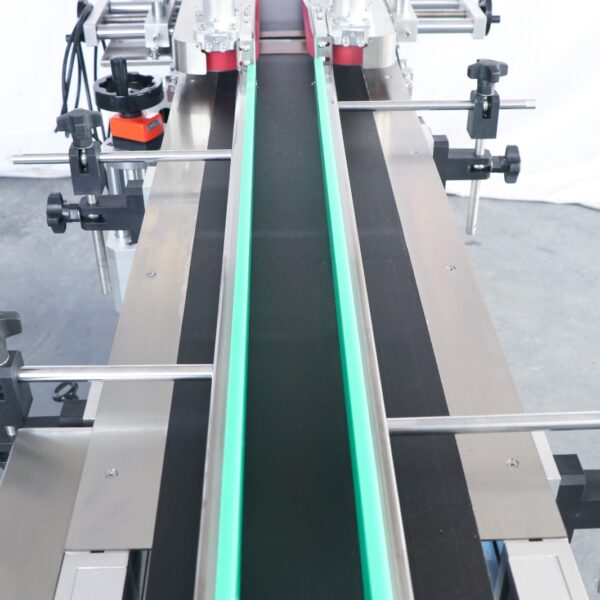

An INOX Drive system equipped with a state-of-the-art 400 Watts motor, offering high precision in affixing the labels, variable speed, with a special high-friction anti-slip belt, 2500 mm (±50 mm) long, 1200 mm (±30 mm adjustable) high from the ground, adjustable belt width up to 200 mm, support with height-adjustable feet, with adjustable side guides, three-phase with thermomagnetic control and start-stop button, specially designed for registration on the bottom of the products.

A Separation System (PRODUCT SEPARATOR), DC Drive (Brushless), electronically regulated by the PLC, accompanied by an adjustable support base and an inverter to regulate the speed, for the separation and controlled feeding of the products at the entrance of the device.

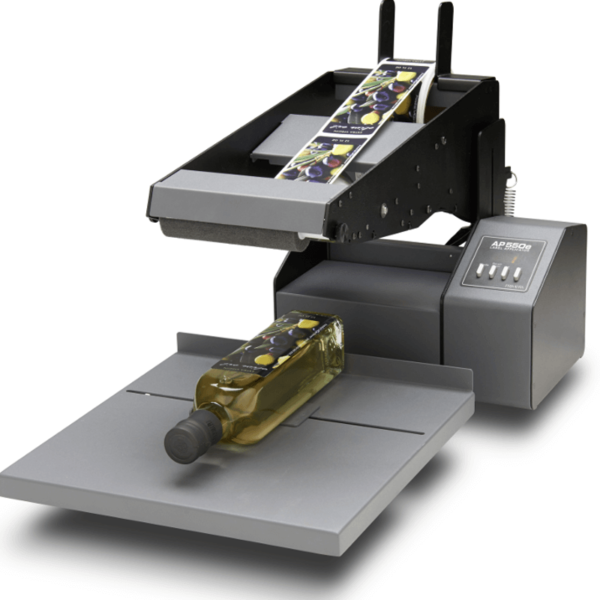

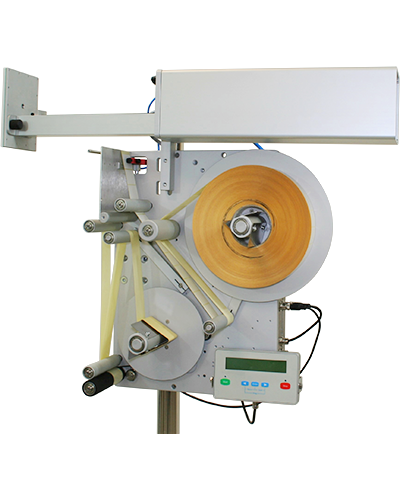

One (1) pc. Industrial labeling system:

-

Easy handling, thanks to the 3-logic menu with LED illuminated indications.

-

Servomotor drive system.

-

LCD screen for easy and quick adjustment.

-

Variable speed control from 10 to 60 pcs/min.

-

Maximum label width 150mm.

-

Maximum label length 300.

-

Maximum linear speed 70m/min.

-

Pasting accuracy up to ± 1-2mm.

-

Automatic calibration at the push of a button.

-

Automatic non-label detection system.

-

English User Interface.

-

Automatic label centering.

-

Number of pieces to which the label is attached.

-

Conveyor belt with single-phase motor width 115mm x length 1500mm

-

Ability to connect to other machines (e.g. fillers)

The main advantages for this application are:

-

Reliable operation combined with minimal need for operator monitoring.

-

Stainless steel and aluminum construction, suitable for any industrial space (with moisture, dust, extreme ambient temperatures, etc.).

- User friendly.

-

Absolute flexibility and excellent bonding quality.

-

Possibility of future upgrade of the layout.

-

The head (labeler) can work simultaneously or independently, according to the user’s choice, thus achieving labeling on the products.

-

The labeler equipped with the offered device can optionally accept an on-line printer (DYNACODE II type), which can print directly on the label any fixed or variable information required such as: product description, ingredients, weight, expiration dates, logos and barcodes thus making the layout a complete Print & Apply solution.